We Make Aerosol Filling Machine.

Dawsom is your reliable manufacturer of customized aerosol filling machine, ranging from lab-scale aerosol filling machine to fully automatic aerosol filling machine for tinplate, aluminum and PET plastic cans to maximize your ROI.

Featured Aerosol Filling Machines

Semi-automatic Aerosol Filling Machine

Model: B-PT-500

This semi-automatic aerosol filling machine is designed for easy operation on a single workstation, making it ideal for entry-level and small production needs. It includes the essential functions of liquid filling, sealing and gas filling. The machine accommodates various can sizes and filling volumes, allowing for quick and convenient adjustments to meet different requirements.

- Compatible with tinplate and aluminum cans

- Maximum liquid filling volume: 500 ml

- Maximum gas filling volume: 250 ml

- Additional customizations available

Semi-automatic Aerosol Filling Machine

Model: B-PT-540

This compact semi-automatic aerosol filling machine is expertly designed to fit on a single workbench, making it ideal for pilot and small-scale production projects. Its minimal footprint allows for easy integration into initial production setups, requiring low investment while offering high automation and user-friendliness. It serves a diverse range of industries, including cosmetics, pharmaceuticals, food, personal care, household products, and more.

- Compatible with tinplate and aluminum cans

- Maximum liquid filling volume: 500 ml

- Maximum gas filling volume: 250 ml

- Automatic can pushing system to minimize operator fatigue

- Additional customizations available

Fully Automatic Aerosol Filling Machine

Model: Q-PT-5000

This fully automatic aerosol filling line includes a can arranging machine, liquid filling machine, valve feeding machine, crimping and gassing machine, weight check machine, water bath leakage checking machine, actuator feeding machine and capping machine. Pneumatic and electrically driven, it is designed for high automation and large-scale production. Suitable for various fields, including cosmetics, pharmaceuticals, household care, food, industrial, and ect.

- Compatible with tinplate and aluminum cans

- Maximum liquid filling volume: 500 ml/head

- Maximum gas filling volume: 250 ml/head

- Additional customizations available

What Sets Us Apart

Competitive Price

By effectively managing our development and production processes, we are able to confidently offer you highly competitive prices without compromising on quality.

Technical Support

Our commitment extends beyond the sale. We offer prompt technical support, including real-time troubleshooting via online video consultations.

Installation & Training

We offer on-site equipment installation and comprehensive training to ensure your team becomes proficient quickly, minimizes downtime, and boosts productivity.

Project Consultation

We offer complimentary consultations for new clients in the aerosol industry, focusing on project investments, production needs, and staffing to support informed decision-making.

Contact Us

Industries We Serve

We understand the challenges faced in various industries and offer tailored aerosol filling machines to meet your specific production needs effectively.

Cosmetics & Personal Care

Topical Proucts

Household Care

Automobile Care

Industry & Construction

Food

Crafting Premium Quality Aerosol Filling Machine

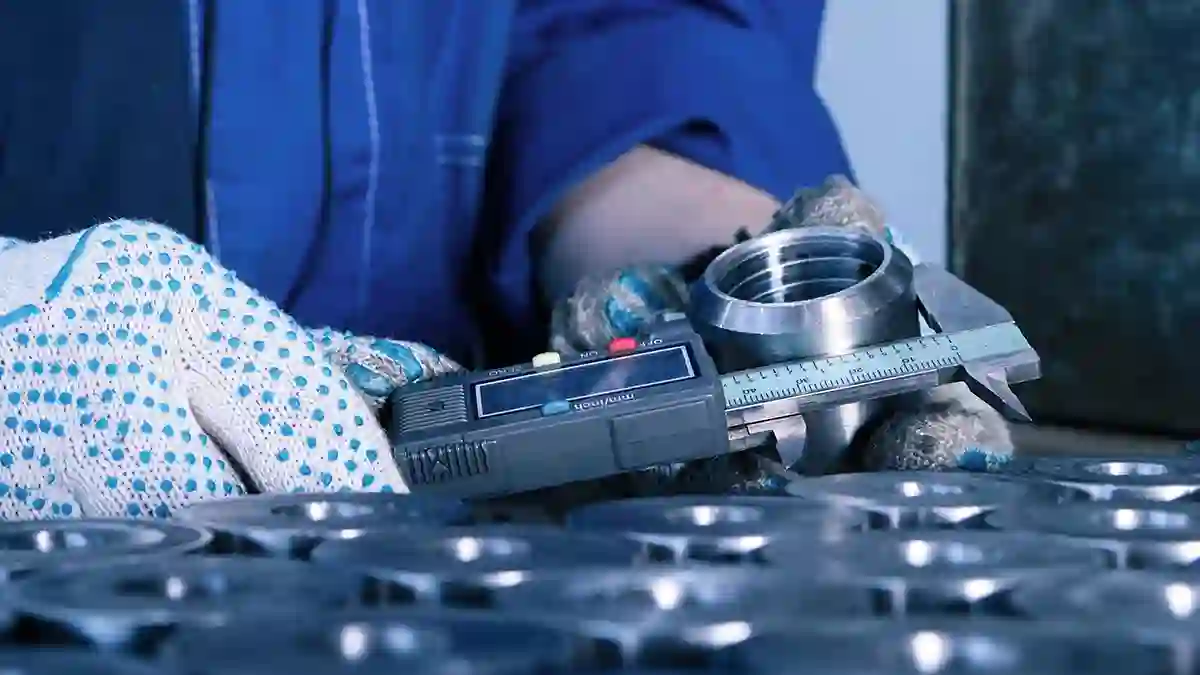

We ensure quality at every stage, from machining to assembly and final testing. Each component is inspected for precision, and advanced instruments verify functionality, guaranteeing every product meets our high standards.

1.

Solution Design

We will engage in thorough communication with our clients to deeply understand their actual needs. This allows us to tailor the most suitable solutions, enabling clients to achieve maximum value from their investments with the most appropriate equipment.

2.

Component Machining

Using advanced CNC technology, each component is machined with precision. This careful process minimizes tolerances, laying the groundwork for a robust system that meets our clients’ high standards for durability and performance.

3.

Component Welding

We employ advanced welding techniques to bond components with strength and integrity. Skilled technicians oversee each joint, ensuring flawless connections that enhance the longevity and safety of the entire assembly.

4.

Component Check

Rigorous inspection protocols assess each component before assembly. By combining automated systems with manual evaluations, we ensure every part meets stringent quality criteria, paving the way for a flawless final product.

5.

Machine Assembly

Each machine is assembled with meticulous care, integrating all components seamlessly. Our efficient assembly line ensures that clients receive equipment that operates flawlessly from the very start.

6.

Machine Check

Thorough testing on each assembled machine verifies its performance under various conditions. A series of checks ensures optimal efficiency, delivering the reliability our clients expect from our advanced technology.

Proven Client Success Stories